LWB

2004 Long wheel base recumbent bike (LWB)

Project 1/10 model made of brass and paper.

The second born of my conception. This HPV (Human Powered Vehicle) has a steel frame. It needs about 100 hours of work. I learned the welding process on it and the seat is in molded polyester. It allows me to have journey during sunny days. My favorite journey is Ecublens - The cathedral of Lausanne - Ecublens. My longest journey is Ecublens - Aigle - Ecublens (73 mi). I like traveling along the Geneva lake or go to Morges. Its weak point is climbing because of its 40 lb weight and only tree speeds system. The average speed on the level is 15 Mph and my maximum speed is 28.6 Mph. On downhill it works admirably and I reach the 37.3 Mph. It has 20" wheels.

Use: February 2004 to November 2006.

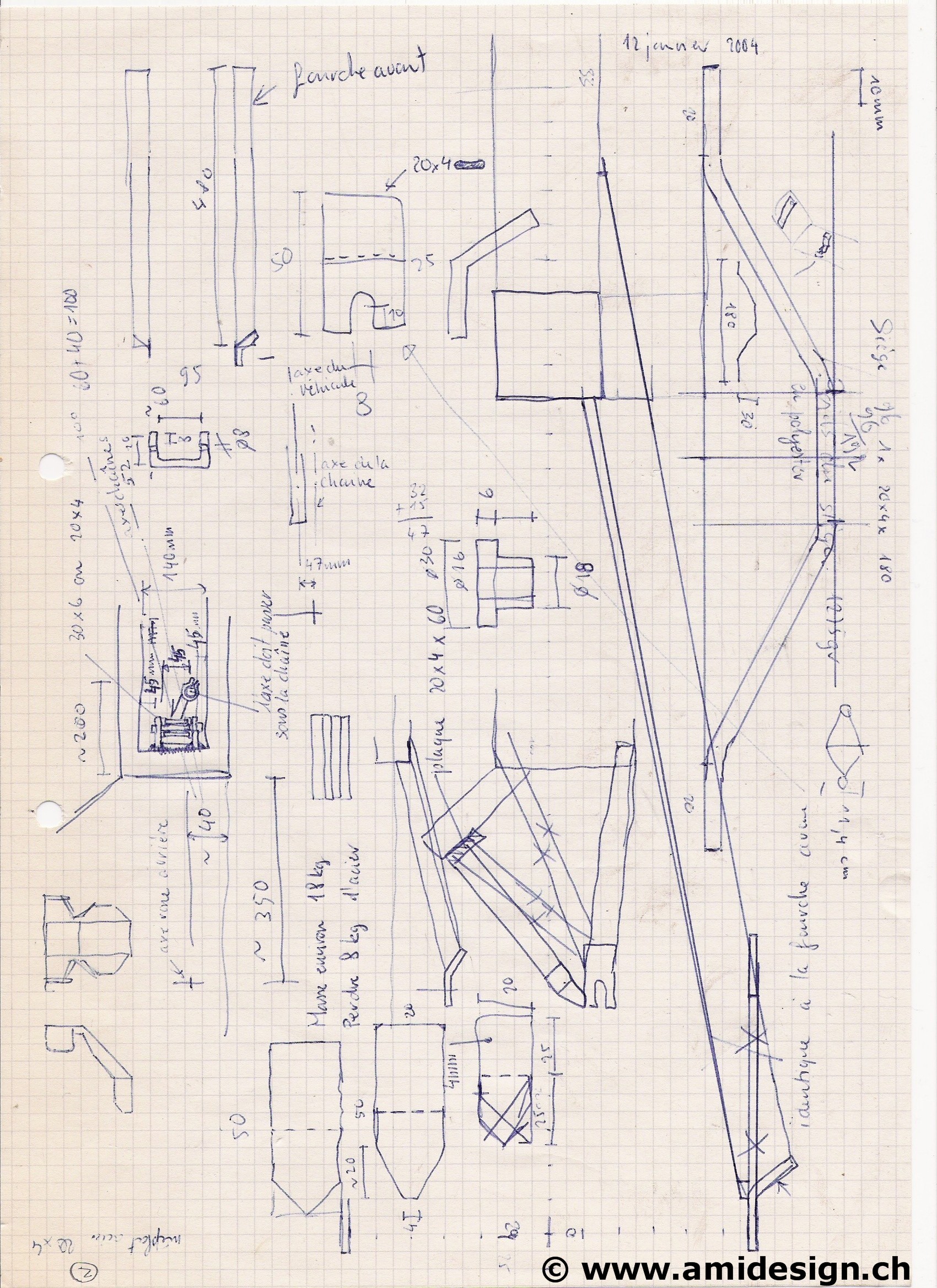

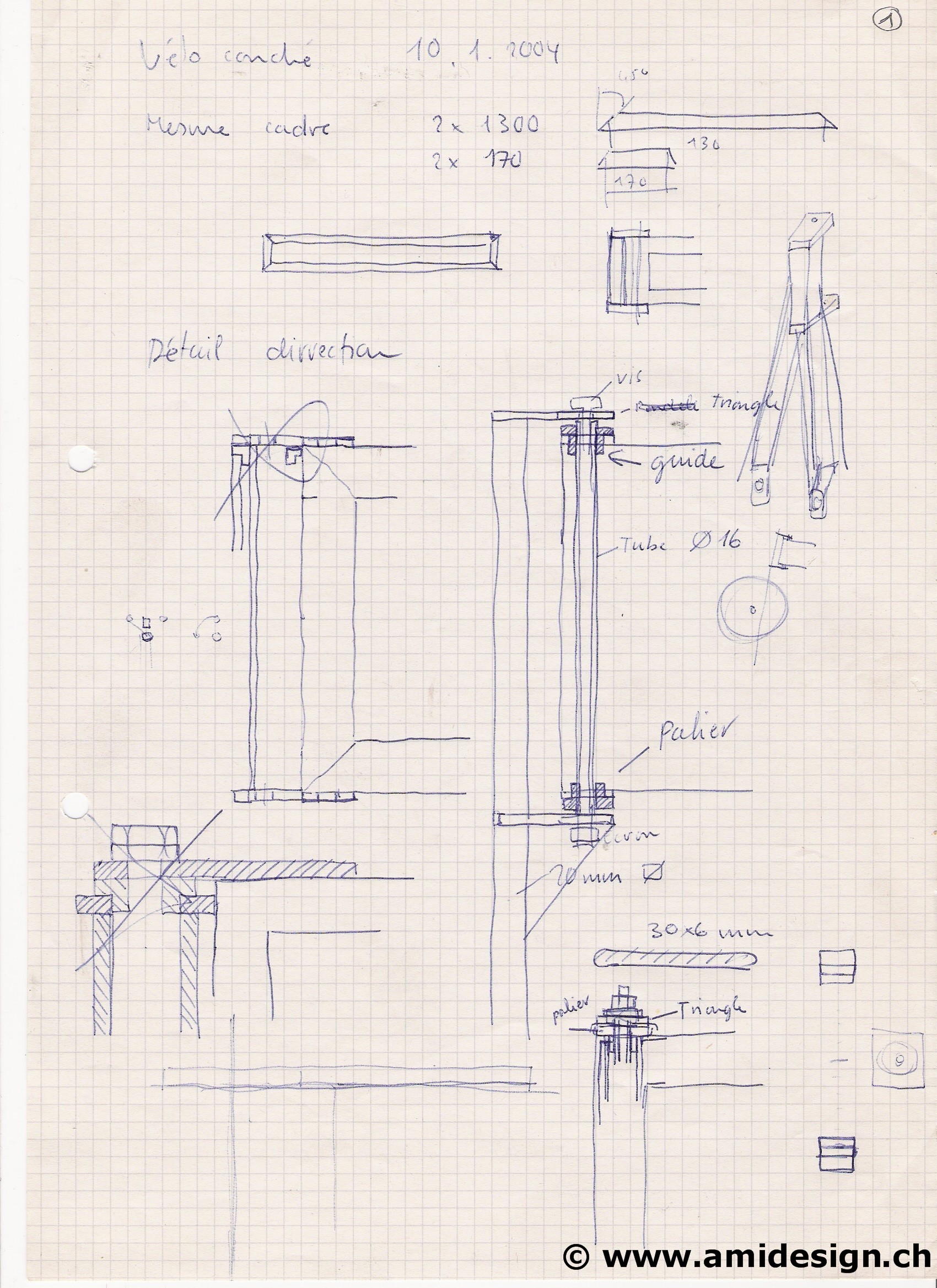

Building notes

Some details

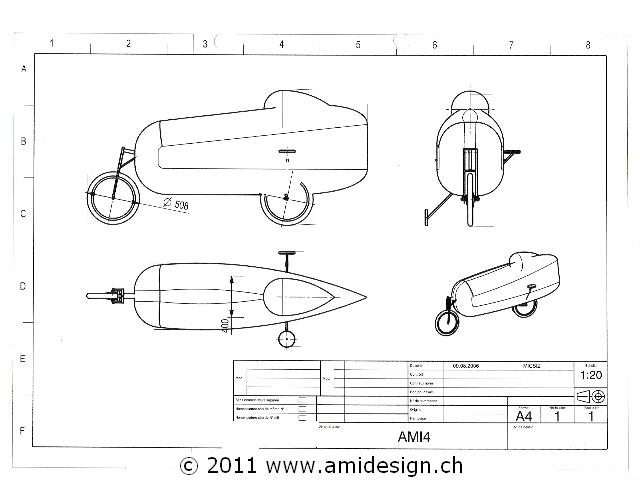

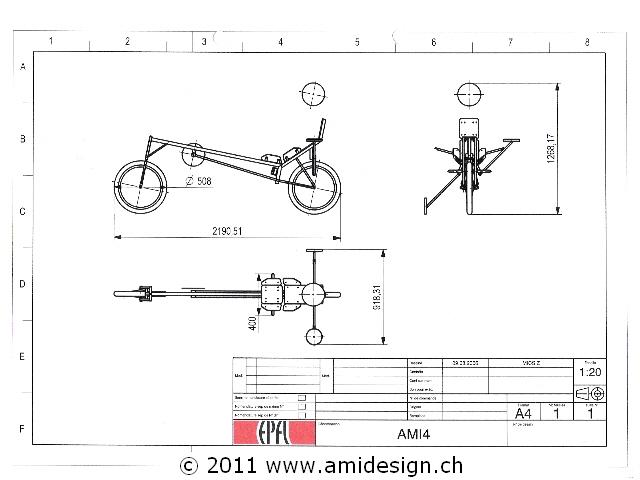

2006 Human powered streamliner vehicle

I decided for my summer holidays to build a new recumbent. This one is an upgrade of the ami-lwb. The frame is lighter. The tires are inflatable up to 110 psi for lowest rolling resistance. The bike receives an aerodynamically body with closed cockpit. In standby mode a lockable landing gear is activated manually. This bicycle allows me to have on flat and short distance a top speed of 80 km/h with homemade 100 teeth gear.

A 100 tooth sprocket.

This is the first picture of acquired parts equipment :

- Two 20" wheels

- Two Maxxis 20" x 1,85" tires

- Two rims scotch

- Two tubes

- One cassette 13 - 32, 7 speeds

- One derailleur

- One shifter

- One speeds shifter

- One meter cable housing

I recovered the pedal unit tube and the brakes supports on an old bicycle. I precisely cut these elements with electric saw and finished it by grinder and file. Then I finished to remove these elements. I weld them on the new frame like for my LWB.

Sealed cartridge unit.

Accessories :

- One rear light

- One halogen front light

- One alternator (dynamo) 6 Volts

- Two pairs V-brakes

- Two levers

- Two cables

Tool for pulling out the pedal levers and tool for the sealed cartridge unit mounting.

I finalized the drawings of the bicycle and cut the steel parts.

I traced, drilled and bend the parts in 20x4 mm steel.

Crank 53 - 39 teeth.

Pedals and handlebar grips.

Two M6 universal joints for steering mechanism.

I have big problems to weld thin metal (millimeter and less).

Welding 1.5 mm square tubes.

The project stop.

These were my welding tools.

Left to right:

- A grinder

- A metal brush

- A peaked hammer

- Clamps

- A welding unit

- Electrodes

- A welding mask

To achieve a 90 assembly I used wood board. For other alignment I used one level.